Liquid cooling is a technology that utilizes liquids to efficiently absorb and dissipate heat from IT equipment, surpassing the capabilities of traditional air-cooling methods. Liquids, with their higher heat-carrying capacity and thermal conductivity, can directly contact heat-generating components. This enables components to be packed closer together, reducing space requirements and enhancing performance.

Additionally, the latest generations of CPUs and GPUs are designed with higher thermal design power than their predecessors. To meet the increasing demands for high-performance computing and AI applications, server manufacturers are incorporating more CPUs and GPUs into each rack. Power densities of 50kW or higher per rack are becoming the standard for data center workloads.

Key Factors Driving Liquid Cooling for Data Centers

The growing use of liquid cooling in data centers is being fueled by several important trends that address the changing requirements of thermal management. Let’s take a closer look at these trends:

- Increasing Power Density and Heat Generation

- Environmental Sustainability Goals

- Space Optimization Imperatives

- Rise of Edge Computing

Types of Data Center Liquid Cooling Techniques

Data center liquid cooling comes in various forms, each designed to meet specific needs and preferences. Three prominent types of liquid cooling systems are:

Rear Door Heat Exchanger:

This system draws ambient air into the cabinet, removes heat using a heat exchanger door attached to the back of the rack, and reintroduces the cooled air into the room. Removing heat closer to the source than air cooling results in greater efficiency.

Direct-to-chip cooling:

Direct-to-chip cooling involves circulating liquid coolant directly over the heat-generating components of individual chips. It ensures precise and targeted cooling, efficiently removing heat at its source. These cooling technologies can remove about 70-75% of the heat generated by the equipment in the rack, leaving 25-30% that must be removed by air-cooling systems.

Immersion cooling:

Immersion cooling submerges entire servers or hardware components in a dielectric fluid, creating a direct and uniform cooling effect. This method minimizes the need for intricate cooling infrastructure and promotes enhanced thermal efficiency.

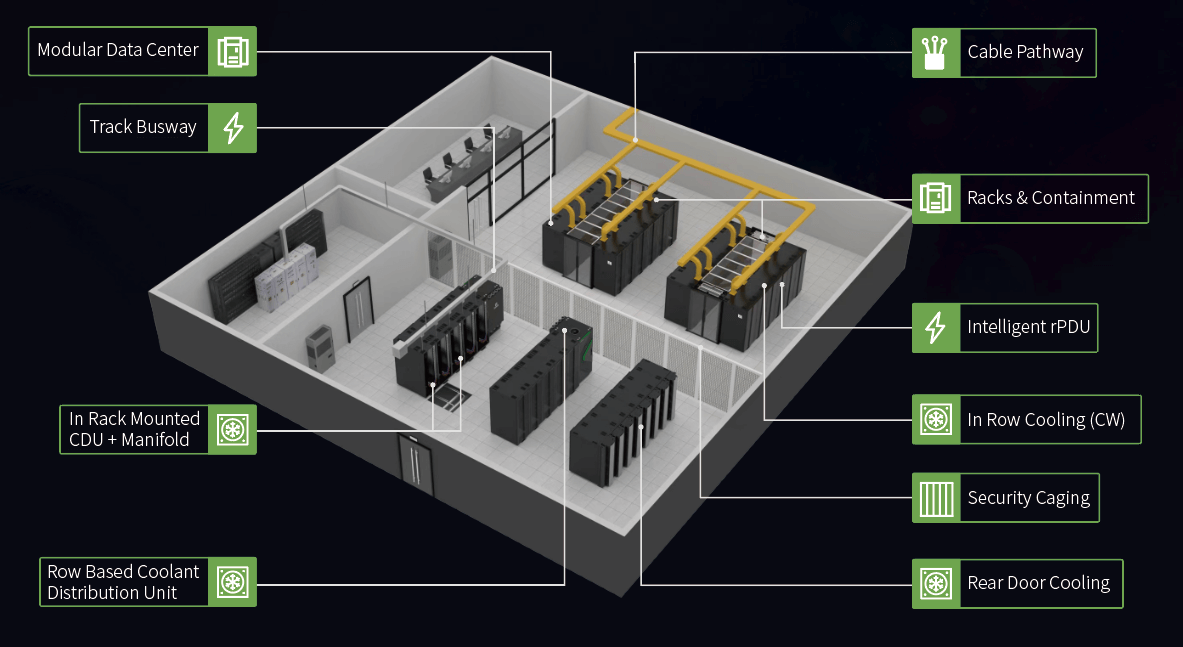

Components of A Liquid Cooling System

A comprehensive liquid cooling system includes several key components, such as cold plates, coolant distribution units, rack-mounted manifolds, Row distribution manifolds, liquid-cooled server racks, and cooling fluid. Each plays a crucial role in ensuring the system’s efficiency and reliability.

Cold Plate:

Cold plates are responsible for transferring heat from surfaces with high heat loads to the fluid used within the liquid cooling system. These cold plates dissipate the heat generated by electronic components with high heat loads, to the coolant that flows to a remote heat exchanger (CDU).

Coolant Distribution Unit:

The Coolant Distribution Unit (CDU) is essentially the heart of the liquid cooling system. It is responsible for managing the coolant flow, ensuring that it is distributed evenly and at the correct temperature across the system. The CDU monitors the system’s pressure, temperature, and flow rate, adjusting parameters dynamically to maintain optimal conditions for heat transfer.

Rack-Mounted Manifolds:

Rack-mounted manifolds provide an interface between Cold Plate Loops in the server and the CDUs. INOVA Manifolds are constructed of reliable stainless steel and are combined with dry-disconnect, drip-free quick couplings.

Row Distribution Manifold:

Row distribution manifolds provide an interface between rack manifold/in-rack CDU Loops and the row-based Coolant Distribution unit (CDU). Inova-engineered Manifolds are constructed of reliable stainless steel (SS316 or SS304) combined with sanitary clamps, valves, flow setters, air bleed valves, mounting hardware, and coolant charging. These are assembled, pressure tested and verified at the factory.

Liquid-cooled server racks:

Liquid-cooled server racks are designed to integrate seamlessly with liquid cooling systems. They contain specialized mounts and interfaces for direct-to-chip or immersion cooling systems, enabling direct heat transfer from the servers to the liquid coolant.

Cooling fluid:

The cooling fluid is selected based on its thermal conductivity, electrical resistance, and chemical compatibility with system components. Common fluids include water, glycol mixtures, and synthetic oils, each chosen for their unique properties to suit specific operational requirements.

Evaluating the Efficiency of Liquid Cooling

In evaluating the efficiency of a liquid cooling system, it is crucial to consider metrics like the capacity for heat removal, energy consumption and sustainability. These measures are essential in gauging the system’s ability to handle the thermal load of a data center and its influence on total energy use.

Metrics for Assessing Efficiency:

Efficiency in liquid cooling systems is accurately assessed using metrics such as Coefficient of Performance (CoP), Energy Reuse Effectiveness (ERE), and Power Usage Effectiveness (PUE).

Heat Removal Capacity:

The thermal dissipation measures how well a system can transfer heat away from its components. This important measure is usually expressed in watts and depends on the system’s design, including factors such as the flow rate of the coolant and the thermal conductivity of the materials used.

Energy Consumption:

Energy consumption is a critical consideration when evaluating the efficiency of a liquid cooling system. It involves the energy required to run pumps and CDUs, the potential savings from reduced need for air conditioning, and the ability to reuse waste heat.

Sustainability:

Various factors such as energy efficiency, carbon emissions, waste usage, waste management, local ecosystem impact, and scope 3 emissions, data centers can achieve true sustainability.

About The Author

Ravishankar Shanmugasundaram

With over 13 years of experience in data center physical infrastructure design, Ravi brings a wealth of knowledge and expertise to the Inova team.